Advanced ceramic mold forming methods.

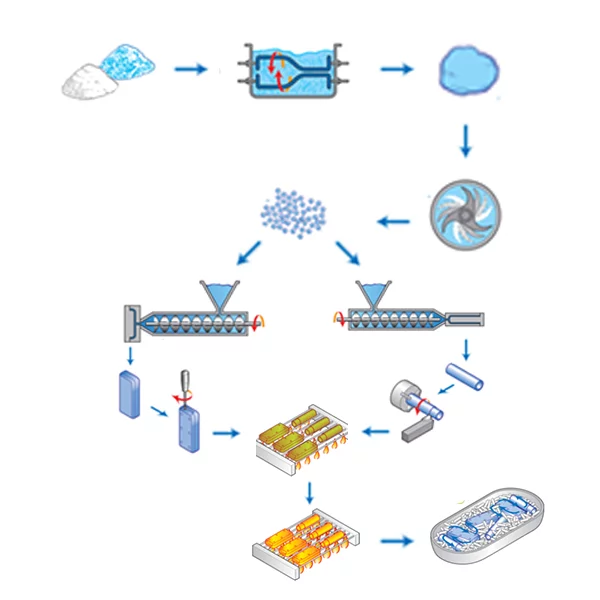

Advanced ceramic molding methods can be divided into dry molding and wet molding. Dry molding including dry pressure, isostatic pressure, ultra-high pressure molding, powder electromagnetic molding. Wet molding can be broadly divided into two categories: plastic molding and colloidal casting. Plastic molding refers to the plastic material pressed into a rigid mold molding methods, including extrusion molding, injection molding and so on.

The services we offer include:Injection Molding (CIM),extrusion molding,thermoforming,Cold Isostatic Press Molding,dry moldingetc.

To Good Ceramics

Advanced Ceramic Injection Molding (CIM).

Ceramic injection molding (CIM) has advantages in mass production of ceramic products with high dimensional accuracy and complex shapes. It has been widely used in aerospace, automotive, machinery, energy, optical communication, life medicine and other fields. It has significant advantages over traditional molding methods:

- Cost-effective technology;

- Suitable for high volume production runs;

- Very high dimensional requirements (≤1% dimensions) are achieved;

- Reduced manufacturing costs.

Currently, materials suitable for ceramic injection molding include: alumina, zirconia, silicon nitride and aluminum nitride.

To Good Ceramics

Ceramic Extrusion Molding.

Zhihao Ceramics offers ceramic tubes or rods made from extruded molds and can be customized in sizes and complex shapes. These products are usually composed of alumina ceramics or mullite, and have functions such as high temperature protection or electrical insulation. The process is widely used in the preparation of ceramic furnace tubes, electromagnetic insulators, catalyst carriers, heat exchanger tubes, and honeycomb ceramic carrier filtration for exhaust gases.

To Good Ceramics

Ceramic Hot Die Casting Molding.

Ceramic hot die casting can be molded in the shape of complex ceramic products, high dimensional accuracy, almost no need for subsequent processing, is the production of shaped ceramic products of the main process. In addition, because the production equipment is cheap, easy to operate, high production efficiency, so the production cost is relatively low. However, due to the low pressure of ceramic hot die casting molding, easy to lead to low product density, high porosity, internal defects, the process is not suitable for the preparation of large ceramic products.

To Good Ceramics

Ceramic isostatic molding.

There are two types of advanced ceramic isostatic press molding, classified as hot isostatic pressing and cold isostatic pressing. Generally isostatic pressure molding refers to cold isostatic pressure (CIP), which is the use of the incompressibility of the liquid medium, the uniform transfer of pressure, pressurized from all directions, to obtain the ceramic product method. Depending on the molding process, it can be divided into two forms: wet bag and dry bag.

Advantages of ceramic isostatic pressing.

- The pressure is transmitted from all directions, the density of the briquette is uniformly distributed, and the strength of the briquette is high;

- The raw billet has high density, fewer uniform defects and lower firing shrinkage than normal dry pressing;

- Complex shapes such as concave and elongated parts can be pressed;

- Low friction loss and low molding pressure;

- Low mold cost.

Applications of Isostatically Molded Ceramics.

- Preparation of high-performance alumina ceramic raw materials, such as ceramic tubes, ceramic rods, ceramic plates and so on;

- Preparation of high performance alumina ceramic part blanks of various shapes;

- Alumina ceramic vacuum switch interrupter “shell” series products, alumina, zirconia ceramic plunger, oil drilling with large size zirconia ceramic cylinder liner.

To Good Ceramics

Ceramic Dry Press Molding.

Dry compression molding of ceramics, also known as molding, is one of the most commonly used molding methods for advanced ceramics production. Dry compression molding is good fluidity, particle grading appropriate granulation powder into the metal mold cavity, through the press head pressure. The large particles are rearranged and deformed and compacted to form a ceramic billet with a certain strength and shape.

Advantages of ceramic dry press molding.

- The process is simple, easy to operate, short cycle time, high efficiency and easy to realize automatic production;

- Raw blanks have high density, accurate dimensions, low shrinkage, high mechanical strength and good electrical properties.

Application of dry press molded ceramic parts.

- It is especially suitable for the preparation of various ceramic products with small cross-section thickness, such as ceramic seals, ceramic spools for valves, ceramic linings, ceramic liners and so on.