What are advanced ceramic materials?

Advanced ceramics is an advanced material, also known as engineering ceramics, technical ceramics, precision ceramics, with the advantages of high hardness, high strength, high temperature resistance, corrosion resistance, low density, electrical insulation, good biocompatibility, dimensional stability, etc., which is widely used in electronic materials, engineering materials, functional materials, optical materials, and medical materials.

Leading manufacturer of advanced ceramics

To Good Ceramics is a manufacturer of advanced ceramics, utilizing cutting-edge technologies in the fields of advanced materials processing and advanced materials manufacturing to produce high-quality ceramics. These processes ensure that the materials meet stringent specifications and performance standards.

Types of advanced ceramic materials

It is known for its excellent hardness and wear resistance, and exhibits good mechanical strength and electrical insulation properties at high temperatures, making it one of the most common and widely used ceramic materials.

It is known for its excellent hardness and wear resistance, and exhibits good mechanical strength and electrical insulation properties at high temperatures, making it one of the most common and widely used ceramic materials.

It is known for its high thermal conductivity and excellent electrical insulation properties, while maintaining good mechanical strength and chemical stability at elevated temperatures, making it an ideal material for high-performance electronics and thermal management applications.

It is known for its excellent hardness and wear resistance, and exhibits good mechanical strength and electrical insulation properties at high temperatures, making it one of the most common and widely used ceramic materials.

Known for its extremely high hardness and thermal conductivity, it also has excellent chemical resistance and thermal stability, making it widely used in abrasives, refractories and semiconductor devices, and is more wear-resistant than alumina and zirconium oxide.

Exhibits excellent thermal conductivity and electrical insulation, while also showing excellent chemical stability at high temperatures, widely used in electronic components and high-temperature furnaces, and its thermal conductivity is higher than that of alumina and silicon nitride.

With extremely high thermal conductivity and electrical insulation, while maintaining chemical stability at high temperatures, it is an ideal material for heat dissipation in electronic devices, and its thermal conductivity is higher than most ceramic materials.

Known for their ease of processing, good mechanical strength and electrical insulation properties, and ability to be precisely molded without significant thermal expansion, these materials are well suited for prototyping and specialized engineering applications.

Zirconia Toughened Alumina (ZTA)

Combining the properties of aluminum oxide and zirconium oxide, they offer high toughness, increased wear resistance and excellent mechanical strength for applications requiring enhanced durability and performance, such as cutting tools and wear parts.

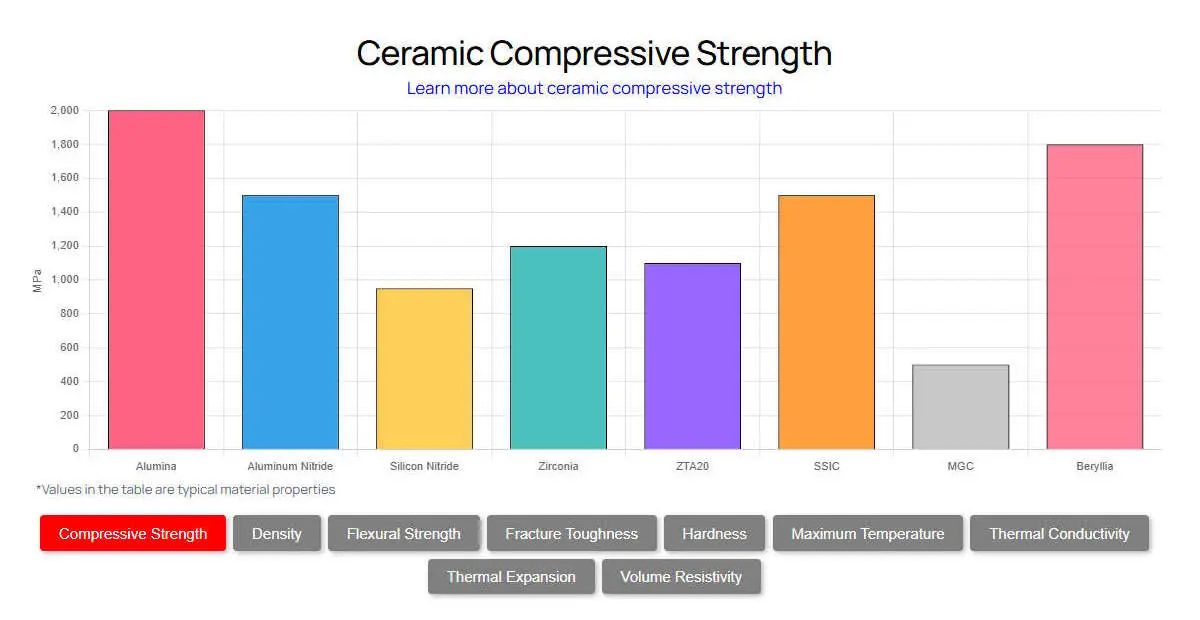

Properties of Advanced Ceramics

Engineering ceramics vary widely in hardness, wear resistance, corrosion resistance, thermal stability and mechanical strength. Customers should consider the operating environment, working conditions, stress, thermal shock and cost when selecting a material to ensure it meets the application requirements and optimizes performance. Click on the icons below to learn moreMaterial PropertiesThe

Uses of ceramic materials

Advanced ceramics can be classified into the following categories based on their properties and uses:

Examples of ceramic materials