What are zirconia (ZrO₂) ceramics?

Zirconium oxide (ZrO₂), also known as zirconia ceramics, is one of the most advanced technical ceramics available today. Zirconia materials have become an integral part of the high-tech industry due to their outstanding mechanical strength, fracture toughness, wear resistance and chemical stability. Zirconia ceramics, known as “ceramic steel”, combine the hardness of technical ceramics with mechanical reliability that surpasses most oxide ceramics.

At Chiho Ceramics, we specialize in precision machining and custom manufacturing of zirconia ceramic components to ensure performance-driven solutions for industries such as electronics, aerospace, chemical engineering, automotive and medical devices. Our advanced machining capabilities, stringent quality control and engineering expertise enable us to provide the best zirconia ceramics according to customer specifications.

Whether you are looking for zirconia ceramic material properties, high precision zirconia ZrO₂ ceramic tubes, or customized black zirconia ceramic parts, ZhiHao Ceramics is a trusted partner in advanced ceramic manufacturing.

jump to

Advantages of Zirconia Ceramics

Zirconia ceramic properties offer a compelling combination of properties that make them superior to many other materials:

At Good Ceramics, we enhance these inherent advantages with proprietary processing techniques to provide the best zirconia ceramics with consistent performance and reliability.

Industrial applications of zirconia ceramics

Zirconia ceramics are widely used in many industries due to their versatility:

Zirconia Ceramics Category

At Zhihao Ceramics, we offer a wide range of zirconia materials, each designed for different performance requirements:

Yttrium stabilized zirconia ceramics (Y-PSZ)

Yttria-stabilized zirconia ceramics (Y-PSZ) are a class of high-performance ceramic materials that partially stabilize tetragonal crystal structures using yttrium (Y₂O₃) as a stabilizer. They are also the most common zirconia ceramics. Yttrium doping effectively solves the phase transition cracking that occurs in pure zirconia at high temperatures, resulting in excellent mechanical properties and long-term stability.

Main features

major application

production and processing

Yttria-stabilized zirconia ceramics are typically made from zirconia nanopowders doped with 3-8 mol% yttrium. They are produced by isostatic pressing or injection molding, followed by high temperature sintering to achieve a dense microstructure. High precision machining processes such as diamond grinding, ultrasonic machining or laser cutting are often required to fulfill the needs of precision parts.

Magnesium Stabilized Zirconia Ceramics (Mg-PSZ)

Magnesium oxide stabilized zirconia ceramics (MgO-PSZ) are partially stabilized zirconia (PSZ) stabilized with magnesium oxide (MgO). They combine the high strength and toughness of zirconia with phase change toughening to provide excellent resistance to cracking and abrasion, making them a key material for structural ceramics.

Main features

major application

Manufacturing process

Mg-PSZ is a high purity zirconia powder doped with about 8-10 wt% magnesium oxide. A dense microstructure is achieved by isostatic pressing and high temperature sintering. The presence of stable cubic and partially deformable tetragonal phases in the grains contributes to its high toughness. Due to its extremely high hardness, machining usually requires precision grinding with diamond grinding wheels or laser machining.

Alumina Toughened Zirconia Ceramics (ZTA)

Zirconia Toughened Alumina (ZTA) is a composite ceramic material consisting of a high content alumina (Al₂O₃) matrix doped with a percentage of zirconia (ZrO₂) particles. The addition of zirconia significantly improves the fracture toughness and crack resistance of ZTA, making it an excellent choice for applications requiring high strength, high wear resistance and high corrosion resistance.

Main features

typical application

production and processing

ZTA is produced by uniformly mixing alumina powder with a specific proportion of zirconia powder (typically 10-20%), dry pressing, isostatic pressing or injection molding, and then sintering at high temperatures. The resulting microstructure shows a uniform distribution of zirconia particles within the alumina matrix, resulting in a toughened surface. Due to its high hardness, machining usually requires diamond tools or laser processing to ensure accuracy.

Alumina Toughened Zirconia Ceramics (ATZ)

Alumina-toughened zirconia ceramics (ATZ) are composite ceramics consisting of a zirconia (ZrO₂) matrix doped with a certain percentage of alumina (Al₂O₃) particles. Unlike ZTA (Zirconia Toughened Alumina), ATZ consists mainly of zirconia. The addition of a small amount of alumina further enhances its strength, hardness and wear resistance while maintaining good fracture toughness.

Main features

typical application

production and processing

ATZs are typically made from a high purity Y-TZP powder matrix with a small amount (typically 10-20 wt%) of alumina. The material is formed by isostatic pressing, injection molding or cast strip molding, followed by high temperature sintering. In the sintered microstructure, the alumina is uniformly dispersed in the zirconia matrix, which strengthens grain boundaries and enhances wear resistance. Due to its high hardness and toughness, machining requires diamond grinding, ultrasonic machining or laser precision cutting.

Zirconia Material Properties

Zhihao Ceramics offers a wide range of zirconia ceramic materials for customers to choose from. The values below are typical material properties and may vary depending on product configuration and manufacturing process. For more details, please feel free to contact us.

mechanical property

| performances | Unit | zirconium oxide | magnesium and zirconium (chemistry) | ZTA |

| color | -- | fig. reactionary | yellow (color) | fig. reactionary |

| intensity | g/cm³ | 6.05 | 5.7 | 4.1~4.38 |

| durometer | GPa | 12.5 | 11.8 | 15 |

| compressive strength | MPa | 2100 | 1750 | 2350 |

| bending strength | MPa | 850 | 900 | 700 |

| Fracture toughness | MPa・m1/2 | 4~5 | >7.0 | 3.5 |

| modulus of elasticity | GPa | 200 | 200 | 310 |

| Poisson's ratio | -- | 0.3 | 0.3 | 0.26 |

thermal performance

| performances | unit (of measure) | zirconium oxide | magnesium and zirconium (chemistry) | ZTA |

| Maximum operating temperature | ℃(No load) | 1000 | 1000 | 1500 |

| Thermal Conductivity @ 25°C | W/(m・K) | 2 | 2.2 | 20 |

| Coefficient of thermal expansion @ 400°C | 1 x 10-6/°C | 10 | 10.2 | 8 |

| specific heat | J/(kg・K) | 460 | 400 | 720 |

| thermal shock resistance | ℃(Put in water) | 300 | 350 | 300 |

Electrical Performance

| performances | unit (of measure) | zirconium oxide | magnesium and zirconium (chemistry) | ZTA |

| dielectric constant | 1MHz | 30 | 28 | 10.2 |

| Dielectric strength (6.35mm) | ac-kV/mm | 9 | 9.4 | 9 |

| dielectric loss | 1MHz | 16 x 10-4 | 10 x 10-4 | 20 x 10-4 |

| Volume Resistance @ 25°C | Ω・cm | >1013 | >1012 | >1014 |

| Volume Resistance @ 500°C | Ω・cm | >103 | >103 | >104 |

Zirconia Ceramics Application Examples

Zirconia (ZrO₂) ceramics from ZhiHao Ceramics are known for their exceptional high strength, excellent fracture toughness, good wear resistance and chemical stability. They are widely used in industries that require the highest mechanical properties and durability. Compared to other structural ceramics, zirconia ceramics have near-metal toughness and a unique phase change toughening mechanism, making them advanced ceramic materials that combine hardness and reliability.

Main applications of zirconia ceramics:

Zirconia Ceramics Processing

Zirconia ceramics are known for their exceptional toughness, high strength and superior wear resistance, making them one of the most advanced ceramic materials in precision engineering. Zhihao Ceramics offers a full range of zirconia ceramic machining capabilities to provide outstanding performance, durability, and precision based on customer needs.

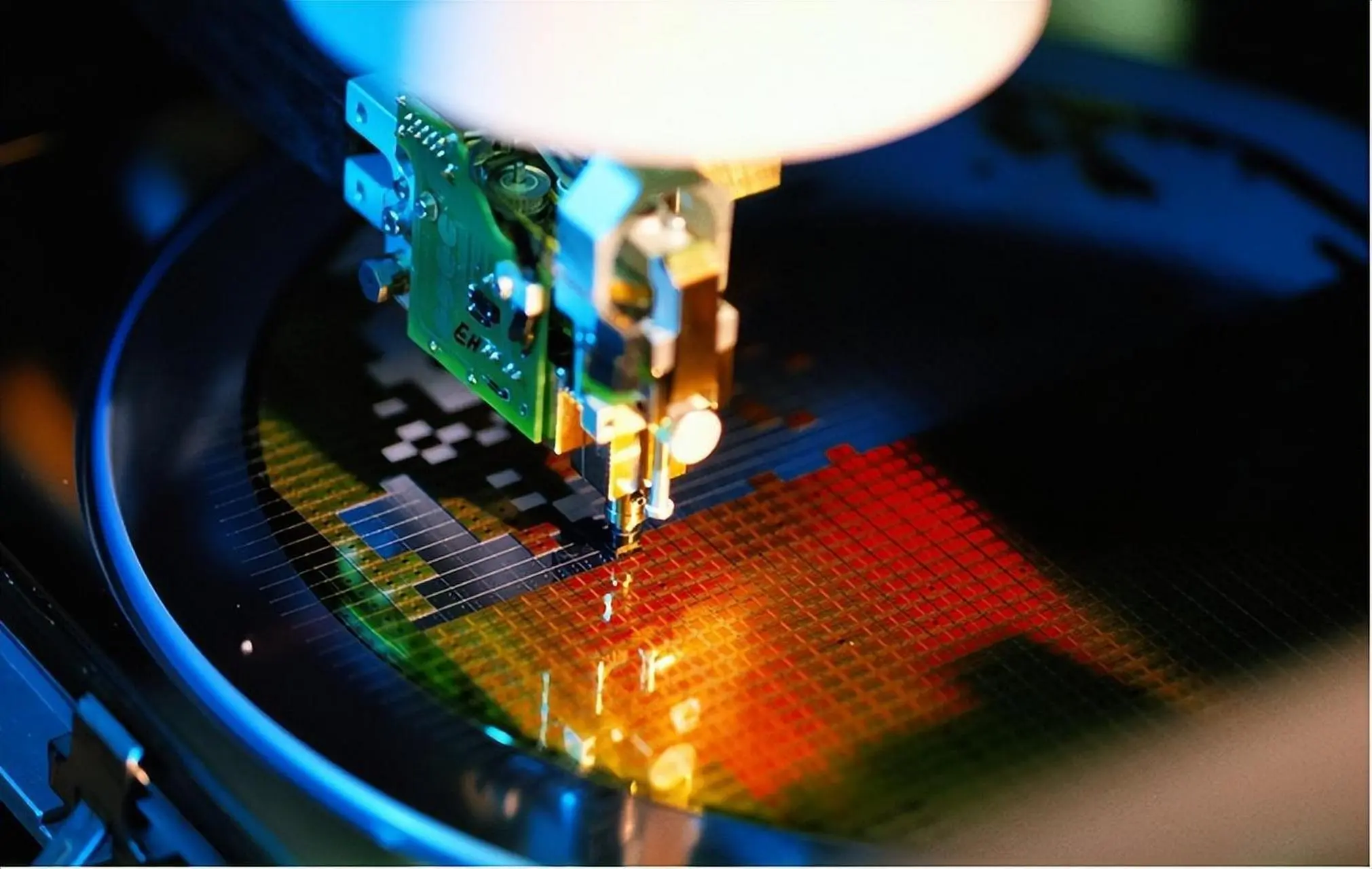

During the machining process, we utilize diamond grinding, precision milling and fine polishing techniques to achieve micron tolerances and superior surface finishes. These capabilities ensure that zirconia ceramic parts meet the stringent structural accuracy and aesthetics required by industries such as medical devices, aerospace and advanced machinery.

With years of technical expertise and state-of-the-art equipment, Great Ceramics not only offers standard parts, but also specializes in customized, complex structural components that require high reliability and long service life.

CNC grinding and milling

CNC milling, turning and grinding to micron tolerances.

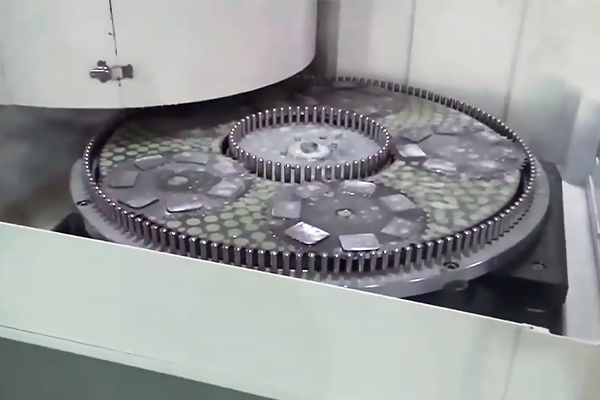

Grinding and polishing

Surface polishing results in smooth surfaces and optical grade surfaces.

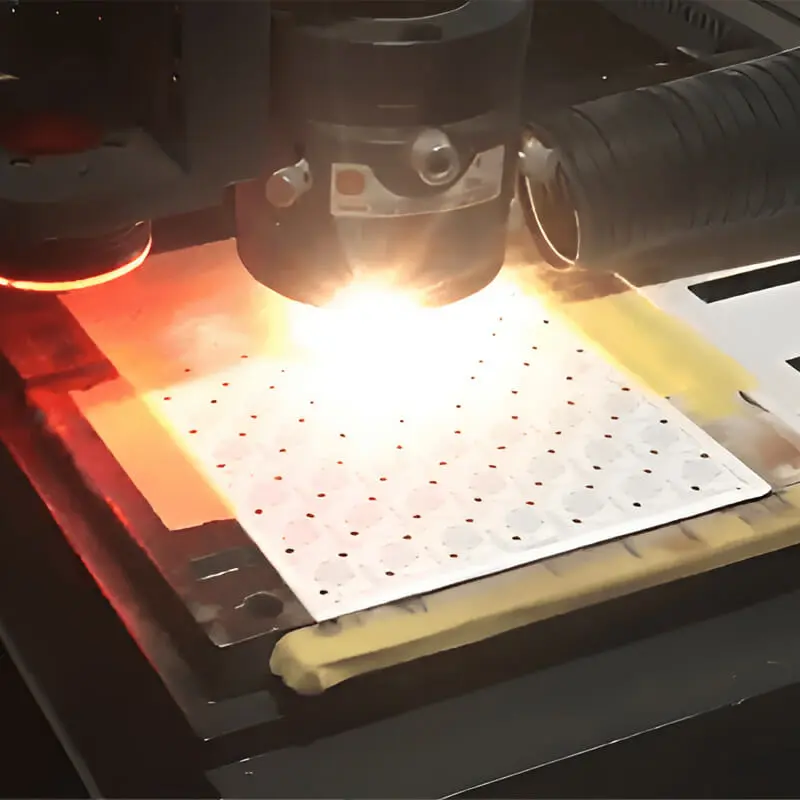

Ceramic Laser Cutting

For laser drilling and cutting of complex geometries.

Metallization and welding

Metallization of ceramic surfaces (Mo/Mn, W).