What are silicon nitride (Si₃N₄) ceramics?

Silicon Nitride (Si₃N₄) is an advanced engineering ceramic known for its excellent mechanical, thermal and electrical properties. This silicon nitride material has become a key solution for industries requiring high strength, wear resistance, thermal stability and reliability under extreme conditions. Silicon nitride ceramics are composed of silicon and nitrogen atoms that form a strong covalent bonding structure that far exceeds the performance of traditional metals and other ceramics, making them indispensable for aerospace, automotive, semiconductor and medical applications.

jump to

Key Benefits of Silicon Nitride Materials

Silicon nitride has a lower coefficient of thermal expansion than other technical ceramics, resulting in excellent resistance to thermal shock. Its exceptional hardness surpasses the high-temperature resistance of most metals, and it also has excellent oxidation resistance. This enables it to withstand the most demanding high-temperature, high-load applications.

Industrial Applications of Silicon Nitride

Silicon nitride (Si₃N₄) ceramics are used in a wide range of industries due to their high strength, excellent wear resistance, outstanding thermal shock resistance and reliable electrical insulation. The following is an overview of their main areas of application:

Available grades of silicon nitride

To Good Ceramics offers a wide range of grades of Chinese silicon nitride ceramics to meet different engineering needs:

Gas Pressure Sintered Silicon Nitride Ceramics (GPSN)

Great Ceramic's Gas Pressure Sintered Silicon Nitride (GPSN) ceramics are high performance silicon nitride materials produced under high temperature nitrogen atmosphere and high pressure. Compared to hot pressed silicon nitride (HPSN), the pneumatic sintering process allows for near-net-shape sintering and the production of large, complex shaped parts while maintaining excellent mechanical and thermal properties, making it more widely applicable in industrial applications.Known for its balanced performance, affordable price, and wide range of applications, GPSN is one of the most widely used types of silicon nitride ceramics available.

Material Properties

typical application

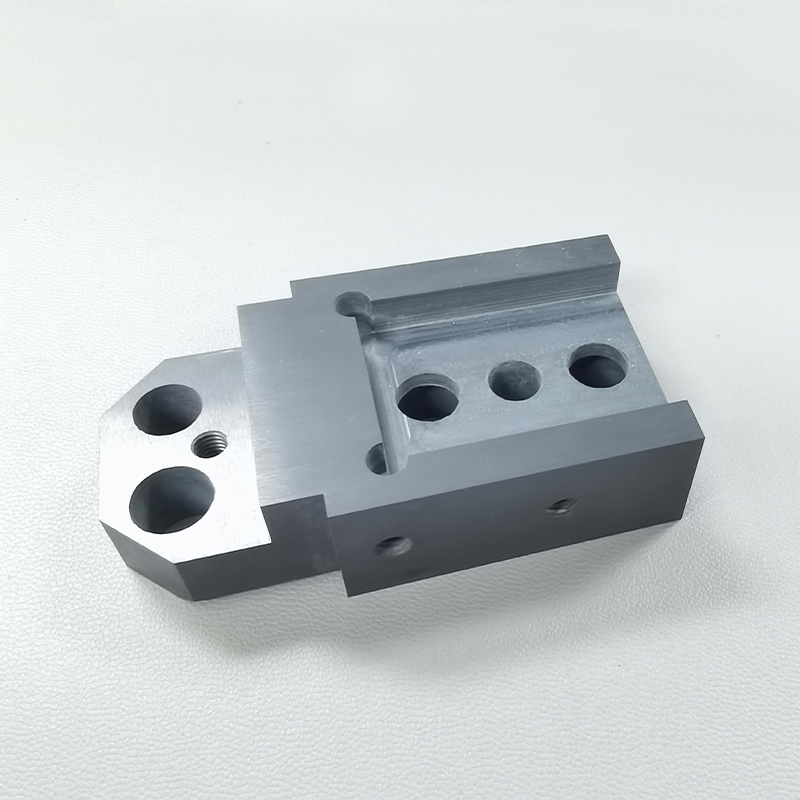

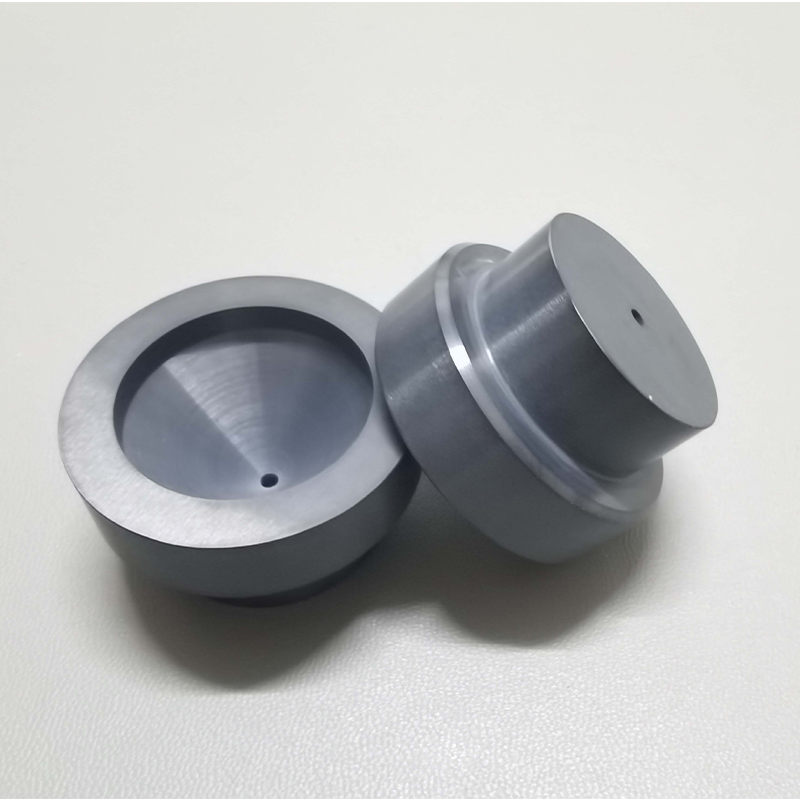

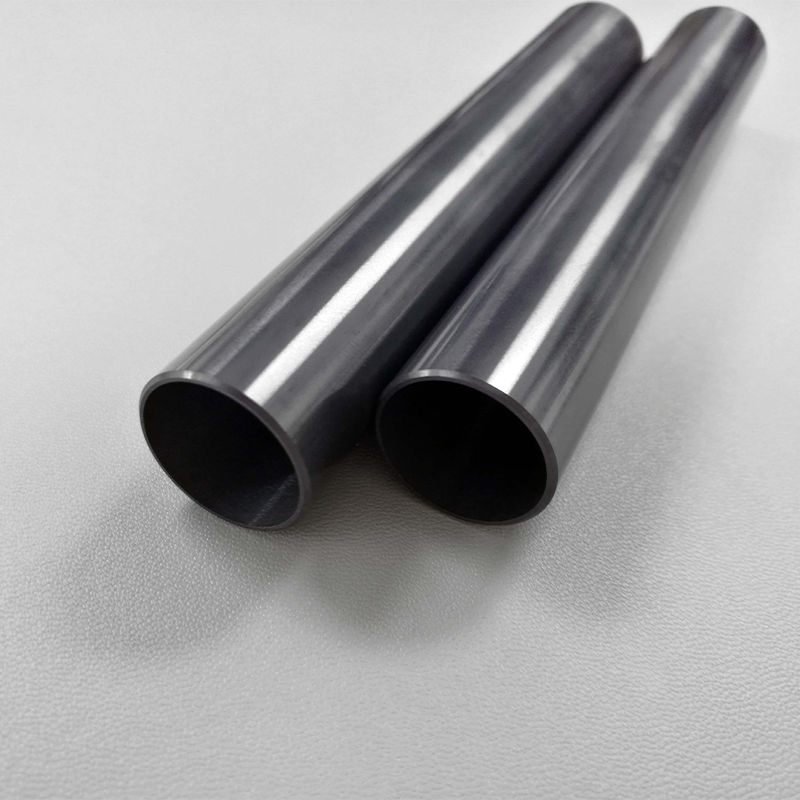

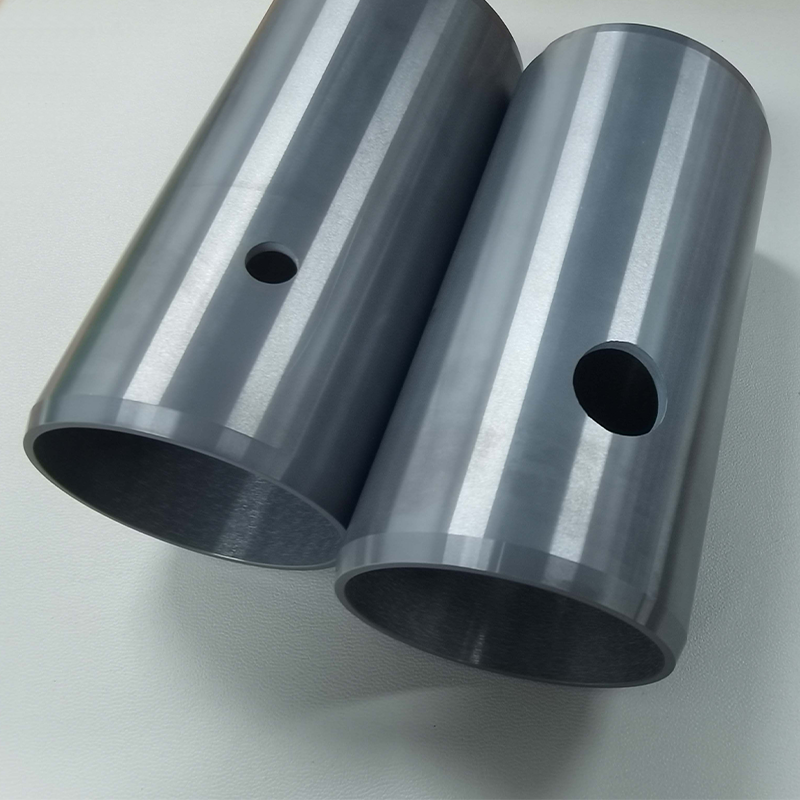

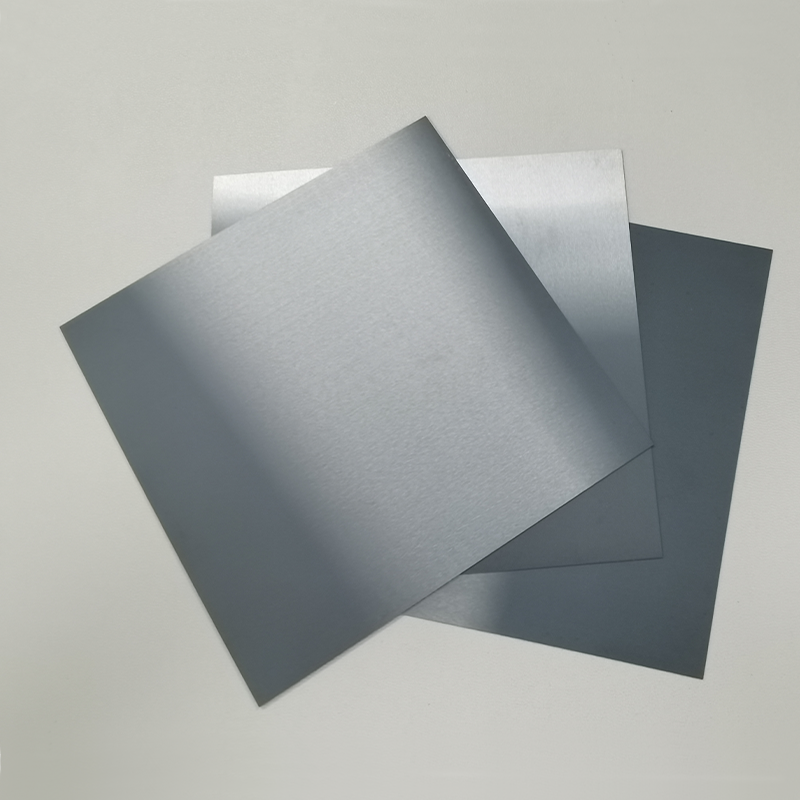

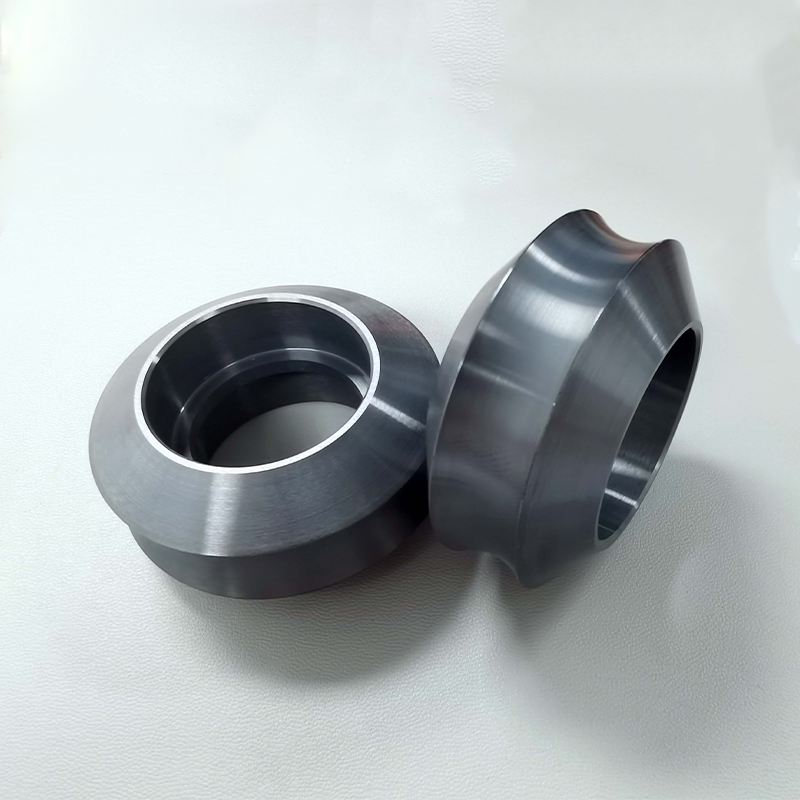

Great Ceramic has comprehensive silicon nitride ceramic machining capabilities, offering a wide range of standardized silicon nitride ceramic rods and plates. great Ceramic also offers a full suite of custom machining services to meet our customers' needs, from molding of complex parts to precision grinding and polishing, to ensure that our products meet the stringent requirements of strength, wear resistance, and reliability in industrial applications. These products are used in bearings, pistons, seals, engine components and other high performance structural parts.

Hot pressed silicon nitride ceramics (HPSN)

Great Ceramic offers Hot Pressed Silicon Nitride (HPSN) ceramics, which are high-density structural ceramics made by simultaneously applying high temperature and uniaxial pressure. They have a dense microstructure, very few defects, and properties close to the theoretical limits, resulting in the highest mechanical and thermal properties of all silicon nitride ceramics. Due to the complex and costly preparation process, hot-pressed silicon nitride is mainly used for high-end and specialized applications.

Material Properties

Application Areas

Hot-pressed silicon nitride ceramics represent the “upper performance limit” of silicon nitride systems due to their excellent mechanical and thermal properties, making them suitable for use in critical core components under extremely harsh conditions. However, due to the limited size and high cost of processing, they are mainly used in applications with very high performance requirements.

Key properties of silicon nitride materials

Zhihao Ceramics offers a wide range of silicon nitride materials for customers to choose from. The values below are typical material properties and may vary depending on product configuration and manufacturing process. Please feel free to contact us for more details.

mechanical property

| characterization | staircase (for residential buildings) | GPSN | HPSN | HTCSNS |

| color | -- | Gray or black | Gray or black | Gray or black |

| intensity | g/cm3 | 3.2 | 3.3 | 3.25 |

| durometer | gigapascal (unit of pressure) | 15 | 16 | 15 |

| compressive strength | megapascal (unit of pressure) | 2500 | 3000 | 2500 |

| bending strength | megapascal (unit of pressure) | 700 | 900 | 600~800 |

| Fracture toughness | megapascal (unit of pressure)1/2 | 5~7 | 6~8 | 6~7 |

| modulus of elasticity | gigapascal (unit of pressure) | 300 | 300 | 300~320 |

| Poisson's ratio | -- | 0.25 | 0.28 | 0.25 |

thermal performance

| characterization | staircase (for residential buildings) | GPSN | HPSN | HTCSNS |

| Maximum operating temperature | ℃ (no load) | 1100 | 1300 | 1100 |

| Thermal conductivity at 25°C | W/(M. Kelvin) | 15~20 | 20~25 | 80~100 |

| Thermal expansion at 40-400°C | 1× 10-6 /C | 3 | 3.1 | 3 |

| specific heat | Joule/(kg/Kelvin) | 660 | 650 | 680 |

| thermal shock resistance | ℃ (into the water) | 550 | 800 | -- |

Electrical Performance

| characterization | staircase (for residential buildings) | GPSN | HPSN | HTCSNS |

| dielectric constant | 1 MHz | 6~8 | 8 | 7.8 |

| Dielectric strength (6.35mm) | AC - kV/mm | 15 | 17 | -- |

| Volume resistivity @ 25°C | Ω・cm | >10 14 | >10 14 | >10 14 |

| Volume resistivity @ 500°C | Ω・cm | >10 10 | >10 10 | >10 10 |

* At not too high temperatures, Si3N4 has high strength and impact resistance, but above 1200 ℃ with the increase in the use of time will be damaged, reducing its strength, more likely to fatigue damage above 1450 ℃, so the use of Si3N4 temperature is generally not more than 1300 ℃.

Silicon Nitride Parts Box

Silicon nitride ceramics (Si₃N₄) are highly regarded for their superior mechanical strength, excellent fracture toughness, low density, excellent thermal shock resistance, and outstanding wear resistance, making them one of the most reliable materials for demanding engineering applications. Below are some of the most common and impactful use cases for silicon nitride ceramic parts across multiple industries:

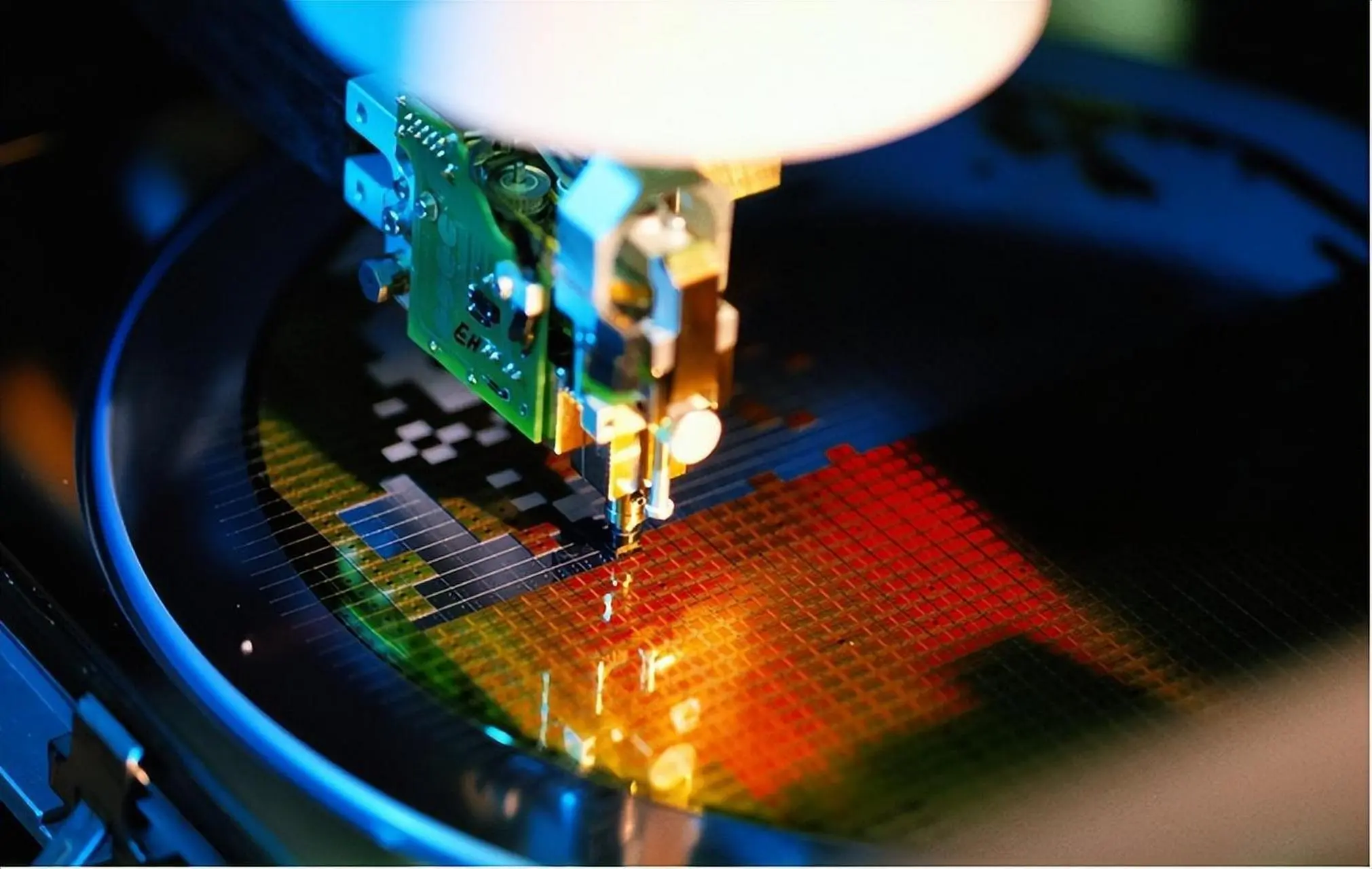

Silicon Nitride Ceramic Processing

Silicon Nitride (Si₃N₄) ceramics are among the hardest industrial ceramics and require advanced machining techniques to achieve precise geometries. Good Ceramics has industry-leading silicon nitride machining capabilities that provide precise, durable and consistent results for mission-critical applications.

We utilize diamond grinding, multi-axis CNC machining, precision grinding and ultra-fine polishing technologies to achieve micron tolerances and superior surface finishes. Our capabilities support high-performance components, including silicon nitride ceramic rods, precision bearing balls, substrates and turbine parts.

In addition, we offer metallization, brazing, assembly and surface treatment services that enable seamless integration of silicon nitride materials into advanced systems. As a leading manufacturer of silicon nitride ceramics in China, we combine cutting-edge technology with in-depth expertise to provide high-quality customized ceramic solutions for the global market.

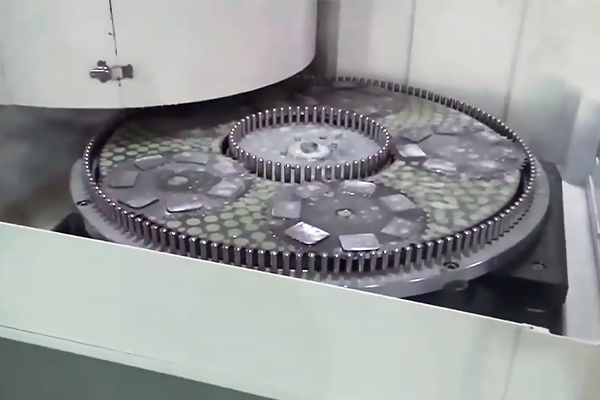

CNC grinding and milling

CNC milling, turning and grinding to micron tolerances.

Grinding and polishing

Surface polishing results in smooth surfaces and optical grade surfaces.

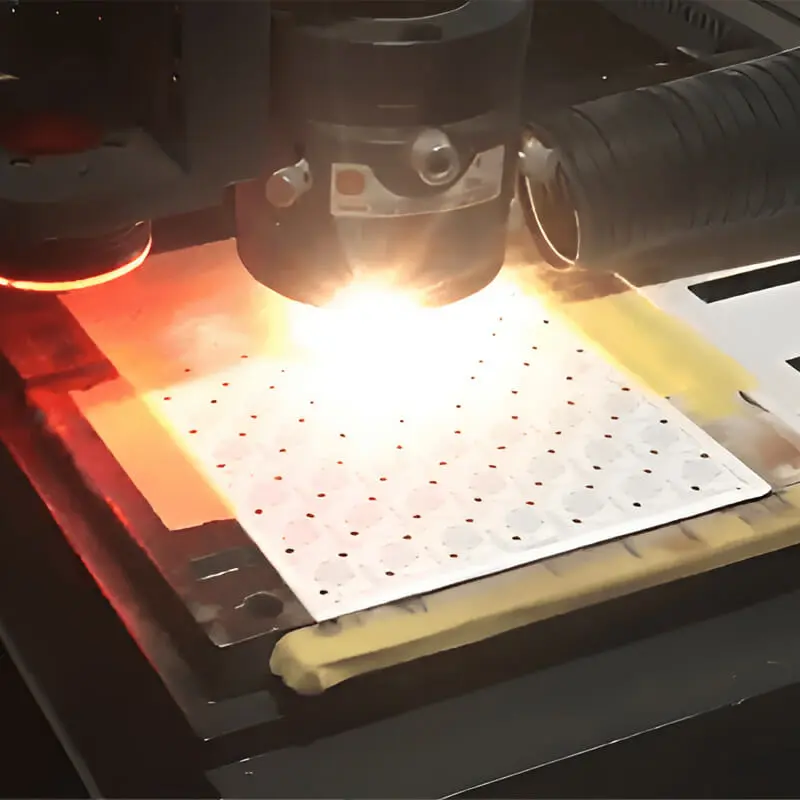

Ceramic Laser Cutting

For laser drilling and cutting of complex geometries.

Metallization and welding

Metallization (Mo/Mn, W) for ceramic-to-metal brazing.

FAQ

Related Products

aluminum nitride

boron nitride