What is machinable glass-ceramic (Macor Ceramic)?

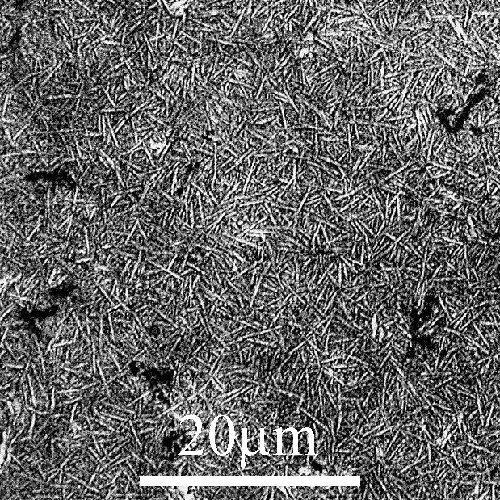

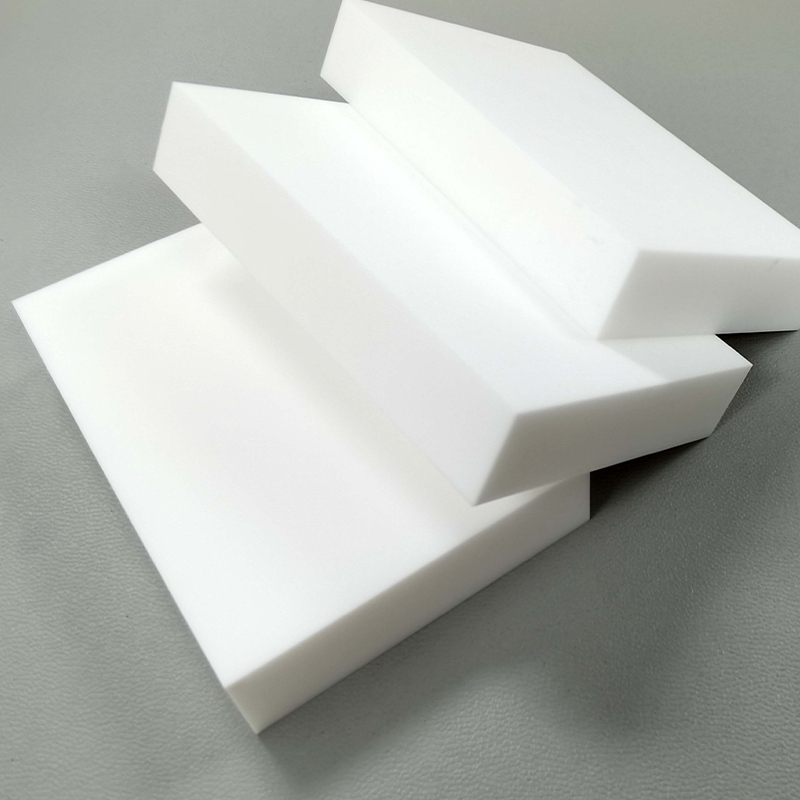

Machinable Glass Ceramics (also known as MGC and Macor Ceramic) is a polycrystalline composite material with a white color. It is a glass-ceramic material with synthetic mica crystals as the main crystalline phase. macor machinable ceramics combine the excellent electrical, thermal and mechanical properties of advanced technical ceramics with the ease of machining using conventional metal working tools. This eliminates the need for expensive diamond grinding and subsequent firing processes, significantly reducing manufacturing time and costs.

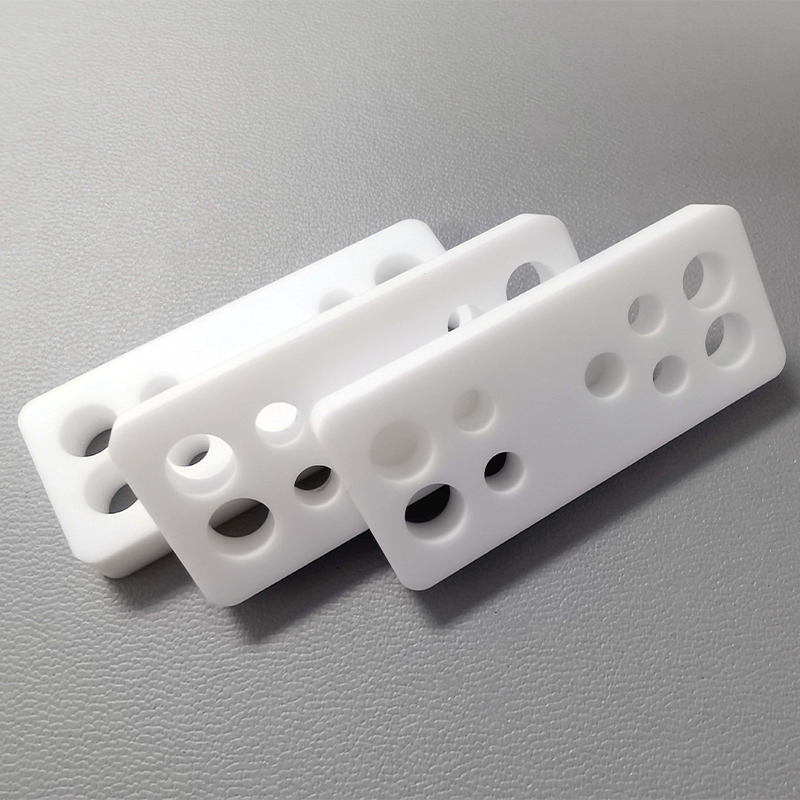

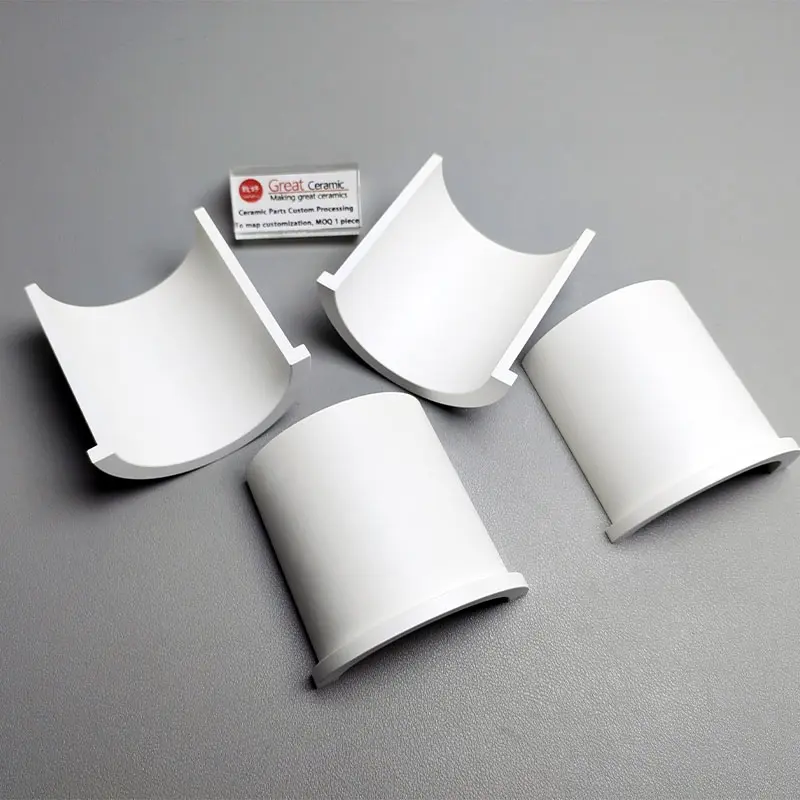

At Good Ceramics, we offer high-performance machinable glass ceramics (MGC), providing high-quality Macor rods, Macor plates, Macor tubes, and custom-machined assemblies for industries that require superior performance, electrical insulation, and thermal stability.

jump to

Advantages of Macor machinable glass-ceramics

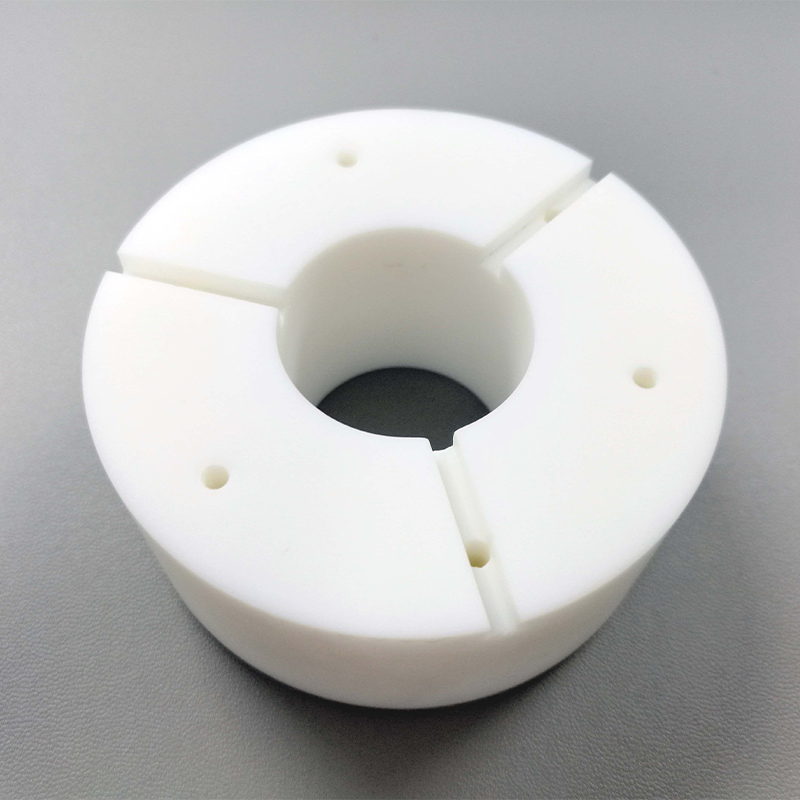

The most outstanding feature of Macor machinable microcrystalline glass is its machinability, which makes it possible to meet the technical requirements of high precision without the need for molds, and can be molded directly to significantly shorten the design and processing cycle. Therefore, Macor ceramics are commonly used for structural ceramic parts with complex shapes, high precision requirements and difficult molding processes, such as thin-walled ceramics and ceramic threads.

Precautions for use

Macor workable glass-ceramics are susceptible to the effects of halogenated acids such as HCl (hydrochloric acid). Tests showed that 2.52 grams (1 cc) of glass-ceramic samples exposed to hydrochloric acid at pH 0.1 lost 100 mg (3.961 TP3T) in 24 hours. Exposure to sodium hydroxide at pH 13.2 resulted in a loss of 0.3961 TP3T in 6 h. Fluorine precipitates when exceeding 600°C (in a vacuum) and manifests itself as boron trifluoride or hydrofluoric acid.

Industry Applications

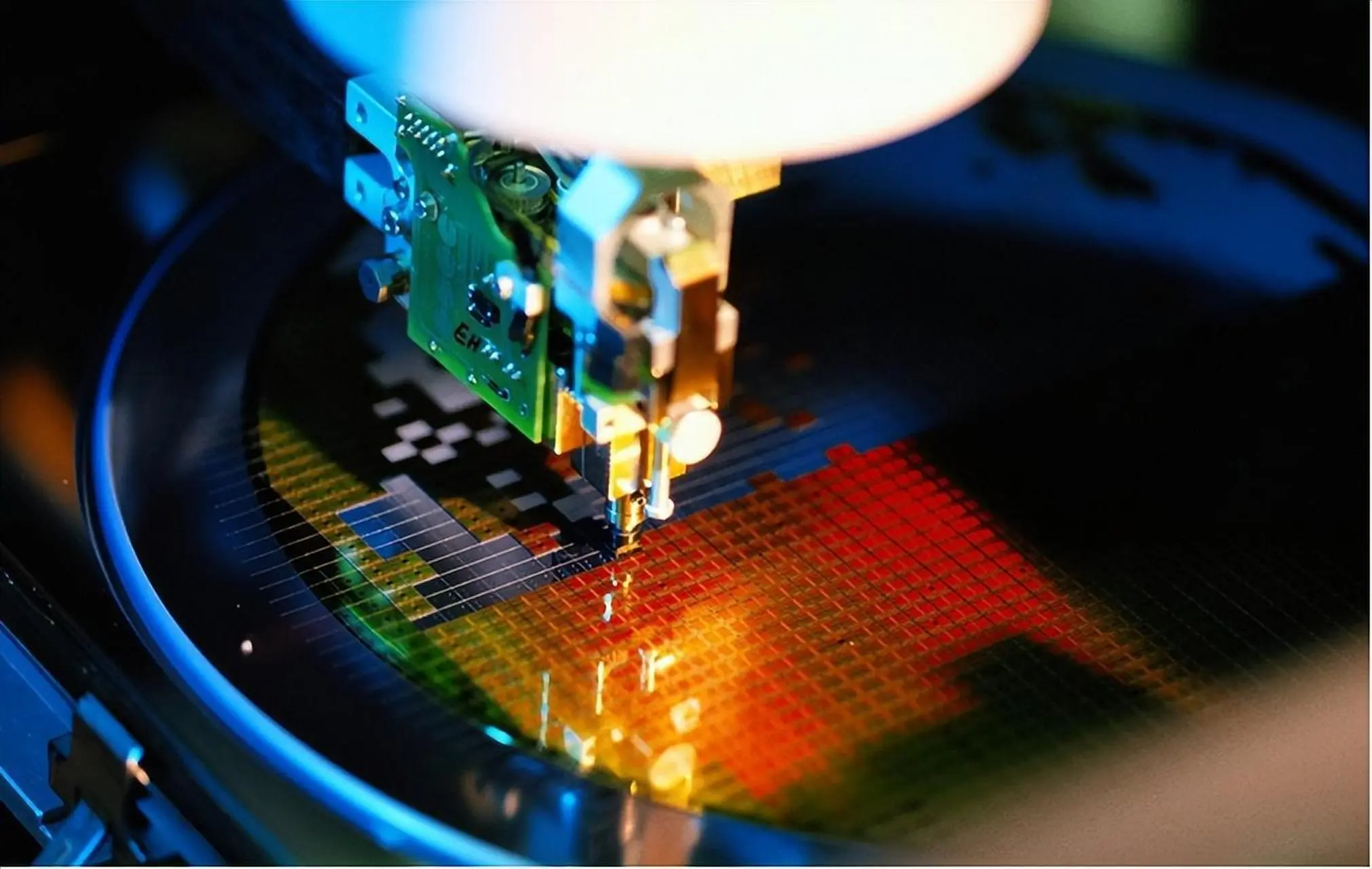

Macor ceramics offer excellent machinability, high thermal stability, electrical insulation, and vacuum and chemical resistance for a wide range of applications - from high-temperature fixtures and insulators in aerospace, semiconductors, and electronics, to radiation-resistant components in medical and nuclear technology, and precision-engineered parts in industrial machinery - making them a versatile material that bridges the gap between traditional ceramics and easy-to-machine engineering materials. It is a versatile material that bridges the gap between traditional ceramics and easy-to-process engineering materials.

Available Macor glass-ceramic grades

“Same reliability, wiser choice.”

Goodwill offers high-performance Macor machinable glass ceramics (also known as MGC). Our MGCs share the same key characteristics as Macor ceramics - superior thermal insulation, excellent resistance properties, and processability - ensuring seamless replacement in demanding applications. In addition, our MGCs offer significant cost advantages, faster delivery and flexible supply.

Zhihao Ceramics combines material supply with CNC machining services to provide ready-to-use customized parts in rods, plates or tubes, all with tight tolerances and smooth surfaces. The products are used in a wide range of aerospace, semiconductor, medical and vacuum technology applications.

Macor can process glass-ceramic compositions

Machinable ceramics are composites made from fluorogold mica in a 45/55 ratio in a borosilicate glass matrix. The composition is as follows:

-

- 46% Silicon dioxide (SiO2) machinable ceramic microstructure

- 17% Magnesium oxide (MgO)

- 16% Aluminum oxide (Al2O3)

- 10% Potassium (K2O)

- 7% Boron (B2O3)

- 4% Fluorine (F)

Key Features of Macor Ceramics

ToHome Ceramics' high-performance MGCs offer similar high-temperature resistance, electrical insulation, and machinability as macor, but with better cost-effectiveness, faster delivery, and customizable precision parts.

Below we have listed the typical properties of MGC, Macor ceramics and Hexagonal Boron Nitride (HBN) ceramics to help engineers better compare the differences in the materials and find the right application.

The following values are typical material properties and may vary depending on product configuration and manufacturing process. Please feel free to contact us for further details.

mechanical property

The mechanical properties of MGC&Macor ceramics are characterized by “medium strength, easy machining, high dimensional stability, moderate hardness and low weight”.

| characterization | staircase (for residential buildings) | Magna | Markel (name) | Boron hydrobromide |

| color | -- | white | white | white |

| intensity | g/cm3 | 2.48 | 2.52 | 2.0 |

| durometer | gigapascal (unit of pressure) | 2.0 | 2.5 | 0.04 |

| compressive strength | megapascal (unit of pressure) | 508 | 345 | 100 |

| bending strength | megapascal (unit of pressure) | 91.5 | 94 | 30 |

| Fracture toughness | megapascal (unit of pressure)1/2 | -- | 1.53 | -- |

| modulus of elasticity | gigapascal (unit of pressure) | 65 | 66.9 | 71 |

| Poisson's ratio | -- | -- | 0.29 | -- |

thermal performance

The thermal properties of MGC & Macor ceramics are characterized by “high temperature stability, low thermal expansion, low thermal conductivity, thermal shock resistance and thermo-mechanical stability”.”

| characterization | staircase (for residential buildings) | Magna | Markel (name) | Boron hydrobromide |

| Maximum operating temperature | ℃ (no load) | 800 | 800 | 850 |

| Thermal conductivity at 20°C | W/(M. Kelvin) | 1.71 | 1.46 | >30 |

| Thermal expansion at 25-200°Ca | 1× 10-6 /C | 7.38 | 9.3 | >1.8 |

| specific heat | kJ/kg・C | -- | 0.79 | 0.81 |

Electrical Performance

The electrical properties of MGC&Macor ceramics are characterized by “high dielectric strength, high resistivity, low dielectric constant, thermal stability and low dielectric loss”.”

| characterization | staircase (for residential buildings) | MGC | Macor | HBN |

| dielectric constant | 1 MHz | 5.7 | 6.03 | 4.0 |

| dielectric strength | AC - kV/mm | 43.4 | 45 | 79 |

| Volume resistivity @ 25°C | Ω・cm | >10 16 | >10 17 | >10 13 |

Macor Ceramic Parts Application Examples

Macor machinable glass-ceramics offer unique properties including excellent machinability, high electrical insulation, high temperature resistance and zero porosity, making them ideal for a wide range of precision and demanding applications. Below are examples of the most common and impactful applications of MGC and Macor products in a variety of fields:

Macor Ceramics Manufacturing and Processing

At Chiho Ceramics, we cut, drill, tap, and shape Macor machinable microcrystalline glass using standard metalworking tools and techniques such as CNC machine tools, lathes, mills, and drill presses, eliminating the need for costly diamond grinding or sintering post-treatments. This significantly shortens manufacturing cycles and reduces costs, while still achieving micron-level tolerances and meeting the stringent accuracy and surface quality requirements of complex structural components.

With years of technical experience and advanced equipment, we not only provide standardized Macor parts such as Macor rods, plates and tubes, but also customize complex structural assemblies and high-reliability products to meet specific customer needs, helping our customers apply Macor ceramics to a wide range of industrial applications.

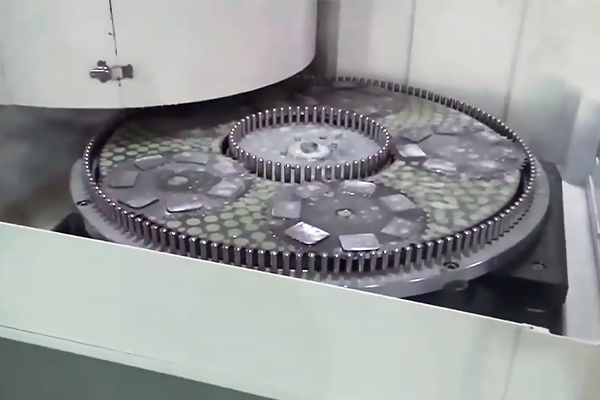

CNC grinding and milling

CNC milling, turning and grinding to micron tolerances.

Grinding and polishing

Surface polishing results in smooth surfaces and optical grade surfaces.

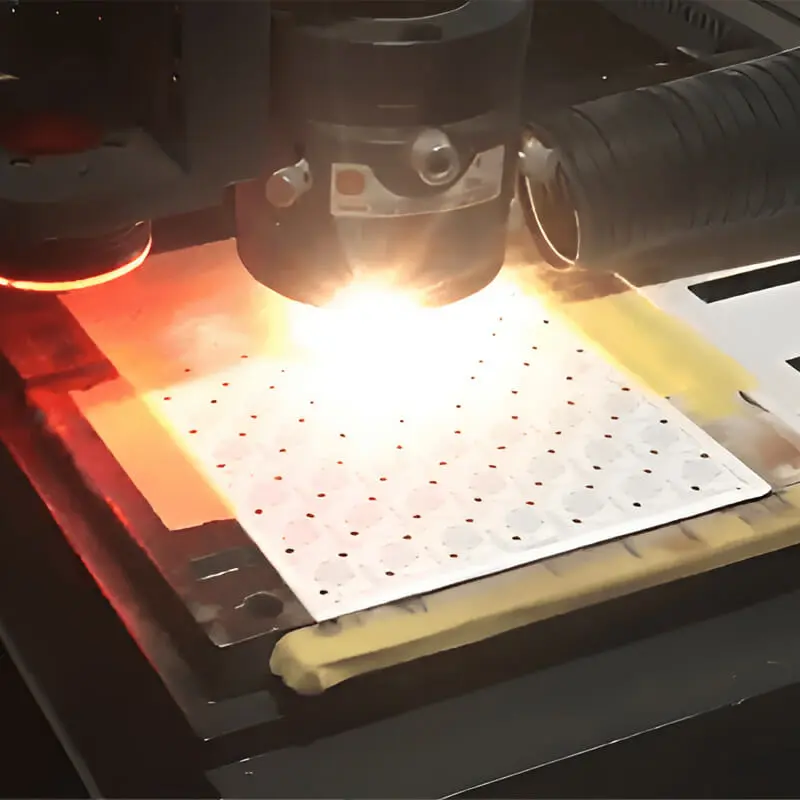

Ceramic Laser Cutting

For laser drilling and cutting of complex geometries.

Metallization and welding

Metallization (Mo/Mn, W) for ceramic-to-metal brazing.

FAQ

Related Products

Aluminum oxide ceramics

boron nitride

aluminum nitride

silicon nitride

Advanced Ceramics Manufacturing Specialist