Advanced Ceramic Material Characterization

Zhihao Ceramics offers a full range of advanced ceramic materials such as oxides, nitrides and carbides with excellent mechanical, thermal, electrical and chemical properties for a wide range of high-demand applications in aerospace, electronics, semiconductors, medical, automotive and energy.

We not only provide materials, but also strive to continuously optimize material design and performance combinations to meet diverse market needs.

This page provides a systematic overview of the basic properties of various commonly used technical ceramic materials and a detailed table of material parameters to help you make scientific decisions when selecting the right material.

jump to

(old) cunning | heat energy | electronic | chemotherapy | appliance | FAQ

mechanical property

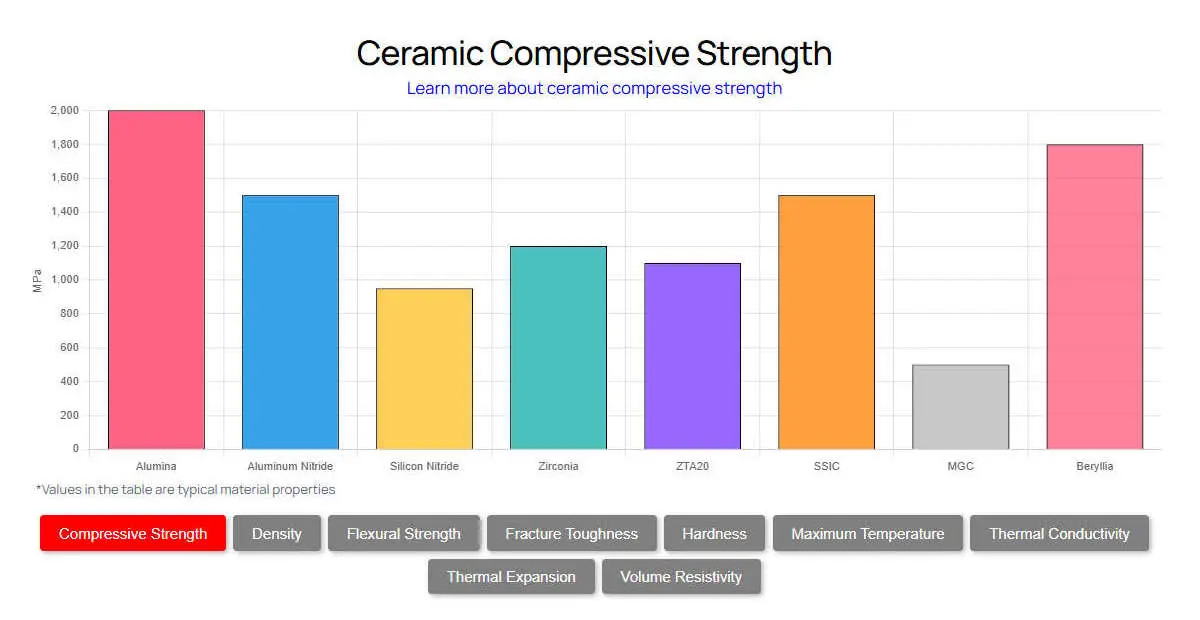

Mechanical properties define the performance of ceramics under mechanical loads such as compression, tension and bending. These properties include ceramic hardness, flexural strength, compressive strength, Young's modulus and fracture toughness. These properties are critical for wear-resistant ceramics, ceramic bearings, seals and high-load structural applications.

Related Keywords Explained:

Mechanical Performance Parameter Table

| makings | Hardness (Hv) | Flexural strength (MPa) | Modulus of elasticity (GPa) | Fracture toughness (MPa-m^1/2) |

| Aluminum oxide (99.7%) | ~1800 | 300-400 | 370 | 3.5-4.5 |

| Zirconia (Y-TZP) | ~1200 | 900-1200 | 210 | 8-10 |

| ZTA20 | ~1500 | 500-700 | 300 | 6-7 |

| silicon nitride | ~1550 | 800-1000 | 320 | 6-8 |

| silicon carbide | ~2500 | 400-550 | 410 | 3.0-4.0 |

| aluminum nitride | ~1200 | 300-400 | 320 | 2.5-3.5 |

| Processable ceramics | ~500 | 150-200 | 65 | 1.5-2.0 |

| Boron nitride (h-BN) | ~100 | <100 | 30 | inapplicable |

| beryllium oxide | ~1200 | 250-300 | 300 | 2.5-3.0 |

thermal performance

In applications involving high temperatures or rapid thermal cycling, thermal properties are critical. Characteristics such as thermal conductivity, coefficient of thermal expansion and maximum service temperature are critical for heat sinks, high temperature insulators and engine components.

Related Keywords Explained:

Thermal Performance Parameter Table

| makings | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10-⁶/K) | Maximum operating temperature (°C) |

| aluminum oxide | 25-35 | 7.5 | 1500 |

| zirconium oxide | 2-3 | 10-11 | 1000 |

| zinc-thiourea | 12-15 | 8-9 | 1450 |

| silicon nitride | 25-30 | 3.2 | 1300 |

| silicon carbide | 120-150 | 4.0 | 1600 |

| aluminum nitride | 170-200 | 4.5 | 1000 |

| Processable ceramics | 1.5 | 9.0 | 800 |

| boron nitride | 30-50 | 1.0 | 900 |

| beryllium oxide | 250 | 8.0 | 1200 |

Electrical Performance

Electrical properties determine the ability of a material to insulate or conduct electricity. Advanced ceramics such as electrically insulating ceramics or dielectric ceramics are widely used in capacitors, insulators, circuit boards and microwave devices.

Related Keywords Explained:

Electrical Performance Parameter Table

| makings | Dielectric strength (kV/mm) | Dielectric constant (1MHz) | Volume resistivity (Ω-cm) |

| aluminum oxide | 10-15 | 9-10 | >10¹⁴ |

| zirconium oxide | 7-9 | 22-30 | >10¹⁰ |

| zinc-thiourea | 9-11 | 15-20 | >10¹² |

| silicon nitride | 12 | 8-9 | >10¹⁴ |

| silicon carbide | ~5 | 9-10 | ~10⁵-10⁶ (semiconductors) |

| aluminum nitride | 12-15 | 8.5 | >10¹³ |

| Processable ceramics | 6-8 | 6 | >10¹² |

| boron nitride | 4-5 | 4 | >10¹⁵ |

| beryllium oxide | 9-10 | 6.5-7 | >10¹⁴ |

chemical resistance

Chemical stability determines a material's ability to withstand harsh chemical environments. Corrosion-resistant ceramics are ideal for chemical reactors, semiconductor equipment and medical sterilization systems.

Related Keywords Explained:

Chemical Resistance Comparison Table

| makings | acid resistance | alkali resistance | antioxidant |

| aluminum oxide | better | desirable | better |

| zirconium oxide | desirable | general | desirable |

| zinc-thiourea | better | desirable | better |

| silicon nitride | better | desirable | better |

| silicon carbide | better | better | better |

| aluminum nitride | general | differ from | general |

| Processable ceramics | general | differ from | general |

| boron nitride | desirable | differ from | Good (inert to HF) |

| beryllium oxide | desirable | general | desirable |

Performance-based applications

Advanced ceramics are widely used in various industries due to their excellent mechanical strength, thermal stability, electrical insulation and chemical resistance. This section introduces application cases based on different performance requirements to help engineers and product developers select the most suitable ceramic materials.

Frequently Asked Questions about Ceramic Material Properties

The selection of advanced ceramics depends on the performance requirements of the specific application. The following are examples based on the above properties:

Let us help you choose the right material

At Chiho Ceramics, we specialize in supplying and processing advanced technical ceramics based on your design and performance requirements. Whether you are developing a new product or improving an existing component, our materials engineers can help you select the best ceramics for your industry.